Peugeot Drives New Revolution in Car Interior Design With Stratasys 3DFashion Technology

Stratasys 3D Fashion technology to support new era for brand’s electric vehicles.

Produces visually impactful interiors incorporating 3D printed patterns onto velvet.

Watch the video of Peugeot CMF designer Maud Rondot talking about the project here.

EDEN PRAIRIE, Minn. & REHOVOT, Israel--(BUSINESS WIRE)-- Stratasys Ltd. (Nasdaq: SSYS), a leader in polymer 3D printing solutions, today announced that global automotive manufacturer Peugeot has integrated Stratasys’ innovative 3DFashion™ technology into the interior of its new Inception concept, achieving a level of resolution that would not have been possible with traditional embellishment methods.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20230622429528/en/

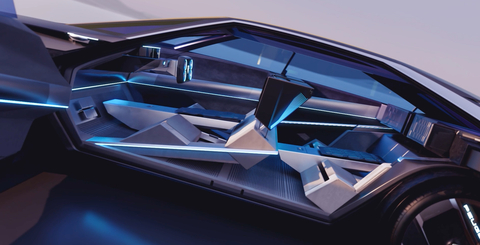

The interior of Peugeot’s Inception Concept car uses velvet material that extends from the seats to the floor and features stunning 3D patterns created with Stratasys’ 3DFashion™ technology. (Photo: Business Wire)

Heralding a new era for the Stellantis-owned Peugeot brand and embodying its vision for future electric vehicles, the Inception concept is the first design manifesto led by the company’s brand design director, Matthias Hossann, and represents a major change for the marque. The car incorporates an interior design described by the company as ‘revolutionary’, and features advanced materials produced exclusively using Stratasys J850™ TechStyle™ 3D printers.

The vehicle interior of the Inception concept is aligned with Peugeot’s new design architecture for electric vehicles. It features a minimalistic cockpit designed to support the car’s overall objective of reinventing the driver experience. Integral to this experience are immersive seats covered with a velvet made from 100% recycled polyester. This velvet extends onto the floor and features stunning 3D patterns created with Stratasys’ 3D printing technology.

“At Peugeot, we always like to combine function with aesthetics,” said Maud Rondot, CMF Designer, Advanced Design Team at Peugeot, the department responsible for the future vision of the Peugeot brand. “Our objective with the Inception concept’s seating area was to modernize the velvet material used and decompartmentalize the design by extending it to also serve as a visually impactful floor mat,” she explained.

According to Rondot, where the floor area space would typically need to be treated with a protective overlay, the Inception concept instead leverages direct-to-textile 3D printing to deliver a unique coalescence of functionality, texture and aesthetics. She believes this would not have been achievable with other technologies.

“Although we have access to relatively flat designs with current embellishment methods, it is not possible to build thickness and height. This is why we turned to Stratasys, and it is thanks to the company’s exclusive 3DFashion technology that we could 3D print directly onto the flexible material,” she added. “Often, there is a delta between what we imagine and what we can obtain, so it was quite magical to see our idea arrive precisely as envisaged and with a remarkable quality of execution.”

A fundamental theme of the Inception concept aims to capture the relationship between materials and light, which required the Peugeot Advanced Design team to use materials that would befit the car’s specific look and embody the brand’s vision for future electric vehicles.

To support this move towards new architecture, new space and decompartmentalization, Peugeot worked with single material effects. This saw the team select a metallic shade for the velvet, which is designed both visually and symbolically to play with light and convey something more futuristic, before using the J850 TechStyle 3D printer to create the semi-transparent ‘micro-architectures’.

“Instead of covering the whole stretch of material, it was really advantageous that we could leave the velvet visible,” Rondot added. “3D printing gave us the ability to modify and reprint the files very easily, but also important is its durability and efficiency; indeed, as a technology it doesn’t require molds, which is revolutionary in terms of industrialization.”

About Stratasys

Stratasys is leading the global shift to additive manufacturing with innovative 3D printing solutions for aerospace, automotive, consumer products, healthcare, fashion and education industries. Through smart and connected 3D printers, polymer materials, a software ecosystem, and parts on demand, Stratasys solutions deliver competitive advantages at every stage in the product value chain. The world’s leading organizations turn to Stratasys to transform product design, bring agility to manufacturing and supply chains, and improve patient care.

To learn more about Stratasys, visit www.stratasys.com, the Stratasys blog, Twitter, LinkedIn, or Facebook. Stratasys reserves the right to utilize any of the foregoing social media platforms, including the Company’s websites, to share material, non-public information pursuant to the SEC’s Regulation FD. To the extent necessary and mandated by applicable law, Stratasys will also include such information in its public disclosure filings.

Stratasys, J850, 3DFashion, and TechStyle are trademarks or registered trademarks of Stratasys Ltd. and its affiliates. All other trademarks are the property of their respective owners, and Stratasys assumes no responsibility with regard to the selection, performance, or use of these non-Stratasys products.

View source version on businesswire.com: https://www.businesswire.com/news/home/20230622429528/en/

Stratasys Corporate & North America

Chris Reese

chris.reese@stratasys.com

+1 651 357 0877

Investor Relations

Yonah Lloyd

yonah.lloyd@stratasys.com

+972 74 745 4919

Europe, Middle East, & Africa

Jonathan Wake / Samantha White,

Incus Media

stratasys@incus-media.com

+44 1737 215200

Brazil, Central America and South America

Erica Massini

erica.massini@stratasys.com

+55 (11) 2626 9229

Israel

Rosa Coblens

rosa.coblens@stratasys.com

+852 9189 7273

Source: Stratasys Ltd.

Released June 22, 2023