Filed by 3D Systems Corporation

pursuant to Rule 425 under the U.S. Securities Act of 1933, as amended,

and deemed filed pursuant to Rule 14a-12

under the Securities Exchange Act of 1934, as amended

Subject Company: Stratasys Ltd.

Commission File No.: 001-35751

The following investor presentation was made available on the 3D Systems Corporation investor relations website (www.3dsystems.com/investor) on June 27, 2023.

Building a Global Leader in Additive Manufacturing JUNE 27, 2023 +

Forward - Looking Statements Certain statements made in this document that are not statements of historical or current facts are forward - looking statements within the meaning of the Private Securities Litigation Reform Act of 1995. Forward - looking statements involve known and unknown risks, uncertainties and other factors that may cause the actual results, performance or achievements of the company to be materially different from historical results or from any future results or projections expressed or implied by such forward - looking statements. In many cases, forward - looking statements can be identified by terms such as “believes,” “belief,” “expects,” “may,” “will,” “estimates,” “intends,” “anticipates” or “plans” or the negative of these terms or other comparable terminology. Forward - looking statements are based upon management’s beliefs, assumptions and current expectations and may include comments as to the company’s beliefs and expectations as to future events and trends affecting its business and are necessarily subject to uncertainties, many of which are outside the control of the company. The factors described under the headings “Forward - Looking Statements” and “Risk Factors” in the company’s periodic filings with the Securities and Exchange Commission, as well as other factors, could cause actual results to differ materially from those reflected or predicted in forward - looking statements. In particular, we note that there is no assurance that a definitive agreement for the transaction referenced in this document will be entered into or consummated or that integration will be successful or synergies will be realized if such transaction were to be consummated. Business combination proposals, transactions and integrations are subject to numerous risks and uncertainties. Although management believes that the expectations reflected in the forward - looking statements are reasonable, forward - looking statements are not, and should not be relied upon as a guarantee of future performance or results, nor will they necessarily prove to be accurate indications of the times at which such performance or results will be achieved. The forward - looking statements included are made only as of the date of the statement. 3D Systems undertakes no obligation to update or revise any forward - looking statements made by management or on its behalf, whether as a result of future developments, subsequent events or circumstances, or otherwise, except as required by law. 2

Additional Information This communication does not constitute an offer to buy or sell or the solicitation of an offer to sell or buy any securities. This communication relates to a proposal which 3D Systems has made for a business combination with Stratasys. In furtherance of this proposal and subject to future developments, 3D Systems (and, if a negotiated transaction is agreed, Stratasys) may file one or more registration statements, proxy statements or other documents with the SEC. This communication is not a substitute for any proxy statement, registration statement, prospectus or other document that 3D Systems and/or Stratasys may file with the SEC in connection with the proposed transaction. Investors and security holders of 3D Systems and Stratasys are urged to read the proxy statement(s), registration statement, prospectus and/or other documents filed with the SEC carefully in their entirety if and when they become available as they will contain important information about the proposed transaction. Any definitive proxy statement(s) or prospectus(es) (if and when available) will be mailed to stockholders of 3D Systems and/or Stratasys, as applicable. Investors and security holders will be able to obtain free copies of these documents (if and when available) and other documents filed with the SEC by 3D Systems through the web site maintained by the SEC at http://www.sec.gov. This document shall not constitute an offer to buy or sell or the solicitation of an offer to sell or buy any securities, nor shall there be any sale of securities in any jurisdiction in which such offer, solicitation or sale would be unlawful prior to registration or qualification under the securities laws of any such jurisdiction. No offering of securities shall be made except by means of a prospectus meeting the requirements of Section 10 of the U.S. Securities Act of 1933, as amended. This communication is neither a solicitation of a proxy nor a substitute for any proxy statement or other filings that may be made with the SEC. Nonetheless, 3D Systems and its directors and executive officers and other members of management and employees may be deemed to be participants in the solicitation of proxies in respect of the proposed transaction. You can find information about 3D Systems’ executive officers and directors in 3D Systems’ definitive proxy statement filed with the SEC on April 5, 2023. Additional information regarding the interests of such potential participants will be included in one or more registration statements, proxy statements or other documents filed with the SEC if and when they become available. These documents (if and when available) may be obtained free of charge from the SEC’s website at http://www.sec.gov.Systems undertakes no obligation to update or revise any forward - looking statements made by management or on its behalf, whether as a result of future developments, subsequent events or circumstances, or otherwise, except as required by law. 3

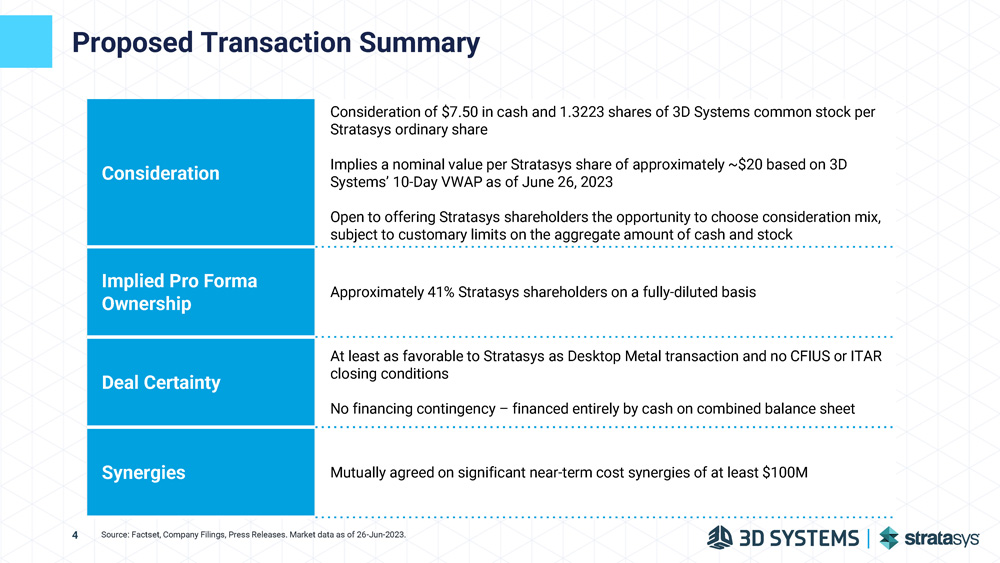

Consideration of $7.50 in cash and 1.3223 shares of 3D Systems common stock per Stratasys ordinary share Implies a nominal value per Stratasys share of approximately ~$20 based on 3D Systems’ 10 - Day VWAP as of June 26, 2023 Open to offering Stratasys shareholders the opportunity to choose consideration mix, subject to customary limits on the aggregate amount of cash and stock Consideration Approximately 41% Stratasys shareholders on a fully - diluted basis Implied Pro Forma Ownership At least as favorable to Stratasys as Desktop Metal transaction and no CFIUS or ITAR closing conditions No financing contingency – financed entirely by cash on combined balance sheet Deal Certainty Mutually agreed on significant near - term cost synergies of at least $100M Synergies Proposed Transaction Summary 4 Source: Factset, Company Filings, Press Releases. Market data as of 26 - Jun - 2023.

An Unparalleled Transaction for Stratasys Shareholders Delivers Exceptional Cost Synergies that Drive Significant Value Creation 2 Secures Higher Value Through Stronger Financial Profile 3 Creates Player with Differentiated Scale and Broadest Capabilities in Rapidly Growing Industry 1 Higher Value. Equal Certainty. The Best Path Forward. 5

Uniquely Attractive Combination 6

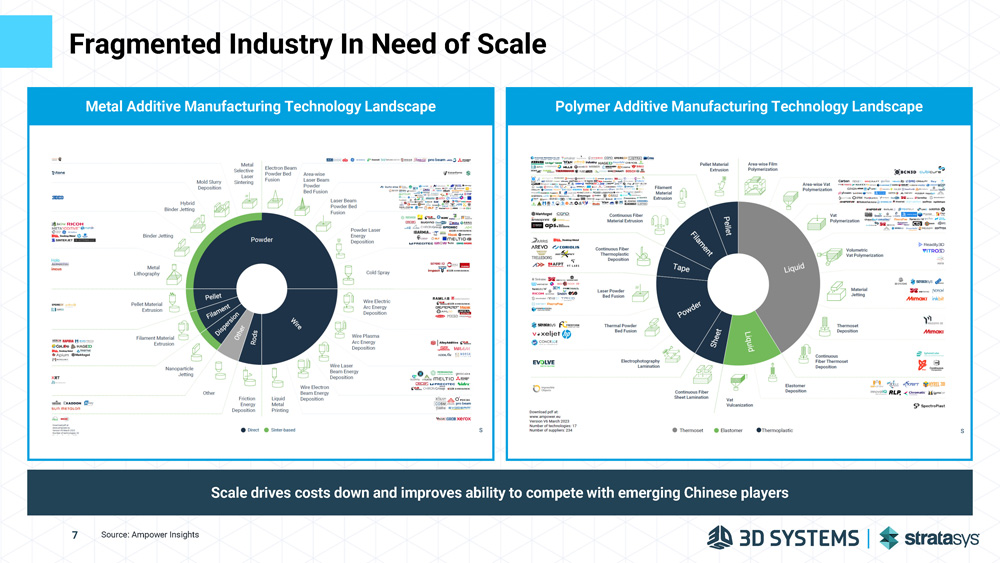

Fragmented Industry In Need of Scale 7 Metal Additive Manufacturing Technology Landscape Polymer Additive Manufacturing Technology Landscape Scale drives costs down and improves ability to compete with emerging Chinese players Source: Ampower Insights

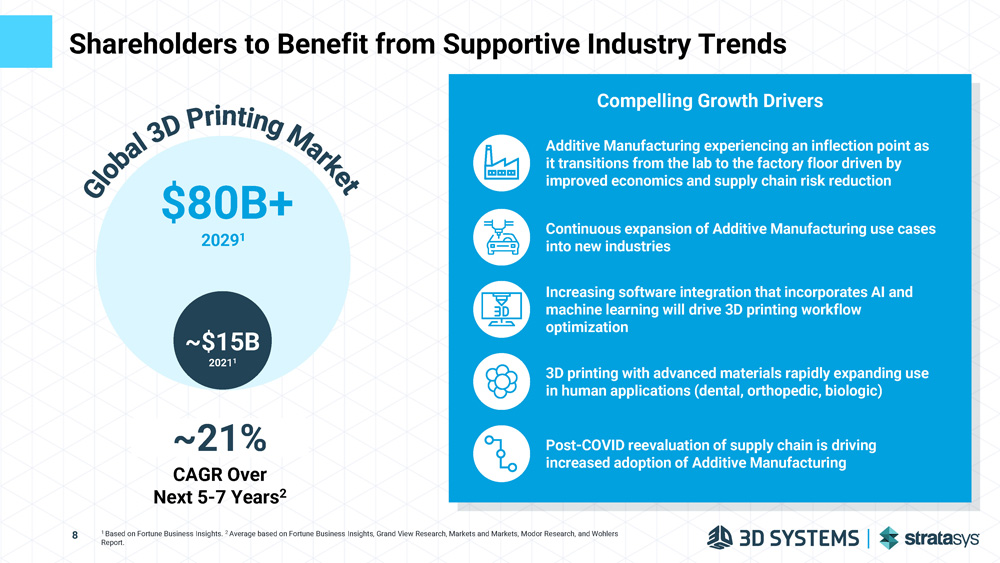

Shareholders to Benefit from Supportive Industry Trends ~$15B 2021 1 $80B+ 2029 1 ~21% CAGR Over Next 5 - 7 Years 2 1 Based on Fortune Business Insights. 2 Average based on Fortune Business Insights, Grand View Research, Markets and Markets, Modor Research, and Wohlers Report. 8 Compelling Growth Drivers Additive Manufacturing experiencing an inflection point as it transitions from the lab to the factory floor driven by improved economics and supply chain risk reduction Continuous expansion of Additive Manufacturing use cases into new industries Increasing software integration that incorporates AI and machine learning will drive 3D printing workflow optimization 3D printing with advanced materials rapidly expanding use in human applications (dental, orthopedic, biologic) Post - COVID reevaluation of supply chain is driving increased adoption of Additive Manufacturing

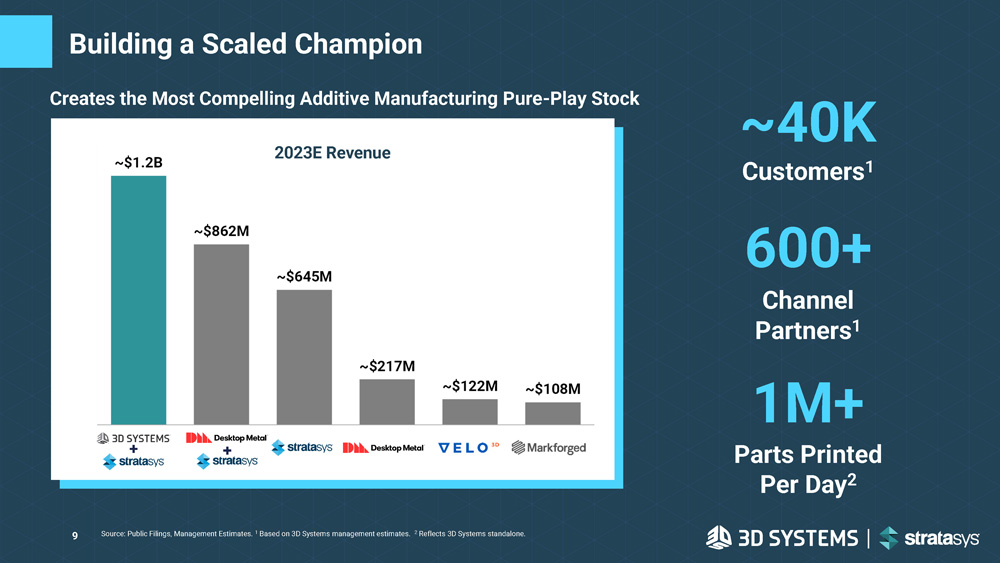

Building a Scaled Champion Source: Public Filings, Management Estimates. 1 Based on 3D Systems management estimates. 2 Reflects 3D Systems standalone. Creates the Most Compelling Additive Manufacturing Pure - Play Stock 9 ~40K Customers 1 600+ Channel Partners 1 1M+ Parts Printed Per Day 2 2023E Revenue

10 Scale Drives Greater Profitability “The problem of this industry (…) no one has scale. So we want to scale. We want an inflection point. We want to be in manufacturing, but at the same time, we don't have the scale to do it. It's all about scale. And we can, as an industry, wait for this scale, but we need the power around in order to be able really to scale.” - Yoav Zeif, Stratasys, CEO Source: Stratasys and Desktop Metal Combination Conference Call and Webcast on 25 May 2023. “ Scale is the most important thing in reaching a high level of profitability.” - Ric Fulop, Desktop Metal, CEO

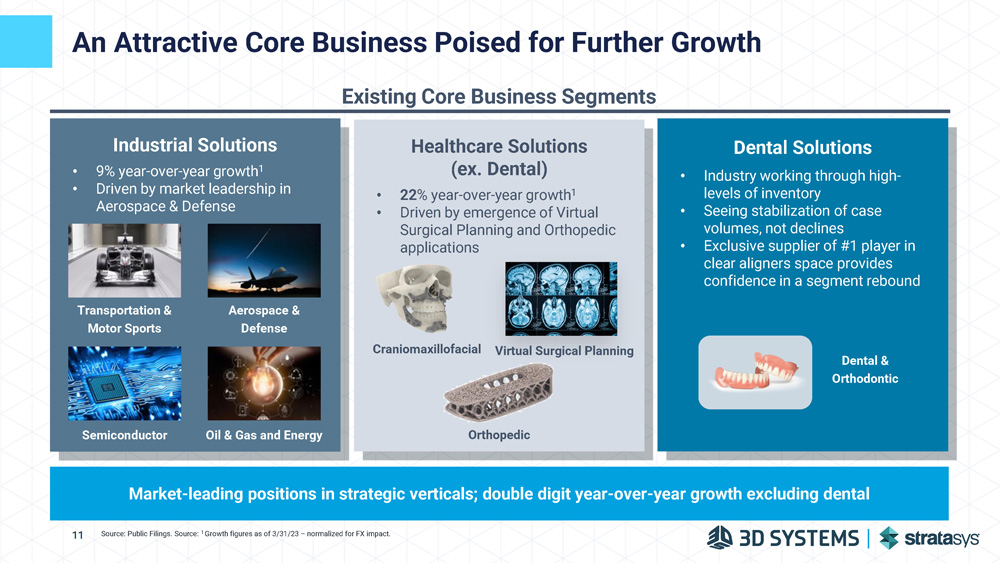

Healthcare Solutions (ex. Dental) • 22 % year - over - year growth 1 • Driven by emergence of Virtual Surgical Planning and Orthopedic applications Industrial Solutions • 9% year - over - year growth 1 • Driven by market leadership in Aerospace & Defense An Attractive Core Business Poised for Further Growth 11 Market - leading positions in strategic verticals; double digit year - over - year growth excluding dental Aerospace & Defense Transportation & Motor Sports Semiconductor Oil & Gas and Energy Craniomaxillofacial Orthopedic Virtual Surgical Planning Source: Public Filings. Source: 1 Growth figures as of 3/31/23 – normalized for FX impact. Dental Solutions • Industry working through high - levels of inventory • Seeing stabilization of case volumes, not declines • Exclusive supplier of #1 player in clear aligners space provides confidence in a segment rebound Dental & Orthodontic Existing Core Business Segments

Non - Organ Tissues Supercharged By a True Growth Engine: 3D Systems’ Incredibly Differentiated Position in Regenerative Medicine 3D Systems Bioprinting Leadership 35+ Years of developing advanced 3D printing applications Organ development partnership since 2017 Acquired in 2021 to expand bioprinting capabilities 3D printed human lung scaffold Human Organs (Lung, Kidney, and Liver) Most Complex Object Ever 3D Printed: • 2 Lobes • 5,000 kilometers of vasculature • 213 Million Alveoli • 44 Trillion Voxels Targeting First in Human Trials (Lungs) 2026 Vascularized Breast Tissue Scaffold for Implantation & Cellularization Drug Development Bioprinted “Organ - on - a - chip” can accurately replicate organ - specific drug response in pre - clinical drug trials h - VIOS 2 chip with perfused vasculature 12

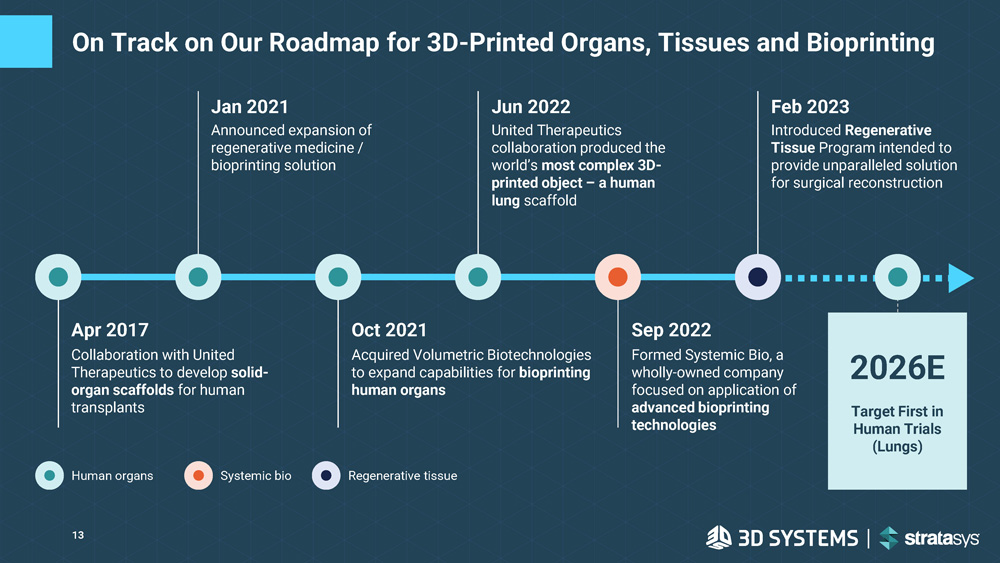

13 On Track on Our Roadmap for 3D - Printed Organs, Tissues and Bioprinting Sep 2022 Formed Systemic Bio, a wholly - owned company focused on application of advanced bioprinting technologies Jan 2021 Announced expansion of regenerative medicine / bioprinting solution 2026E Target First in Human Trials (Lungs) Apr 2017 Collaboration with United Therapeutics to develop solid - organ scaffolds for human transplants Jun 2022 United Therapeutics collaboration produced the world’s most complex 3D - printed object – a human lung scaffold Feb 2023 Introduced Regenerative Tissue Program intended to provide unparalleled solution for surgical reconstruction Oct 2021 Acquired Volumetric Biotechnologies to expand capabilities for bioprinting human organs Human organs Systemic bio Regenerative tissue

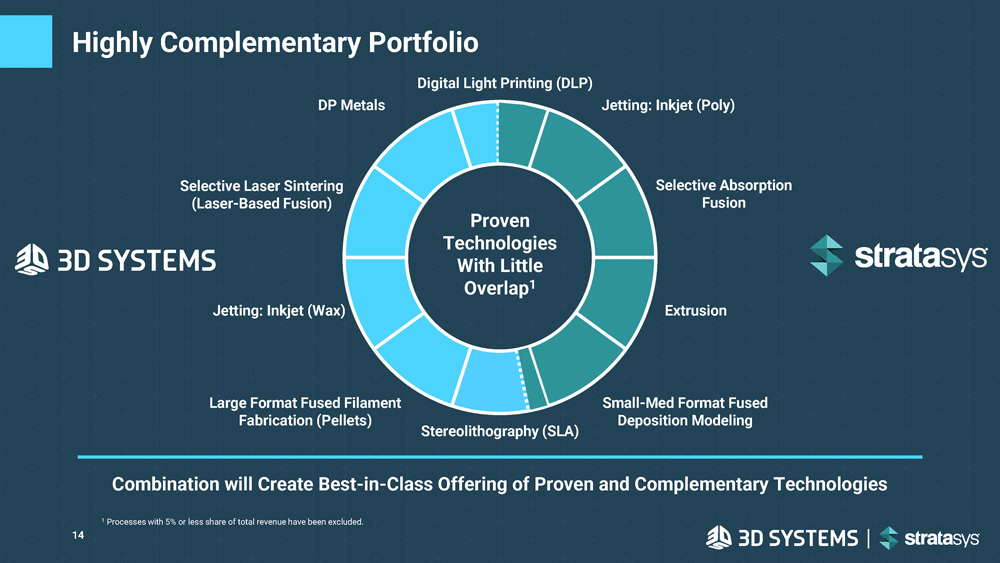

Highly Complementary Portfolio Selective Laser Sintering (Laser - Based Fusion) Large Format Fused Filament Fabrication (Pellets) Jetting: Inkjet (Wax) Jetting: Inkjet (Poly) Selective Absorption Fusion Small - Med Format Fused Deposition Modeling Extrusion Proven Technologies With Little Overlap 1 Combination will Create Best - in - Class Offering of Proven and Complementary Technologies Stereolithography (SLA) Digital Light Printing (DLP) DP Metals SSYS 1 Processes with 5% or less share of total revenue have been excluded. 14

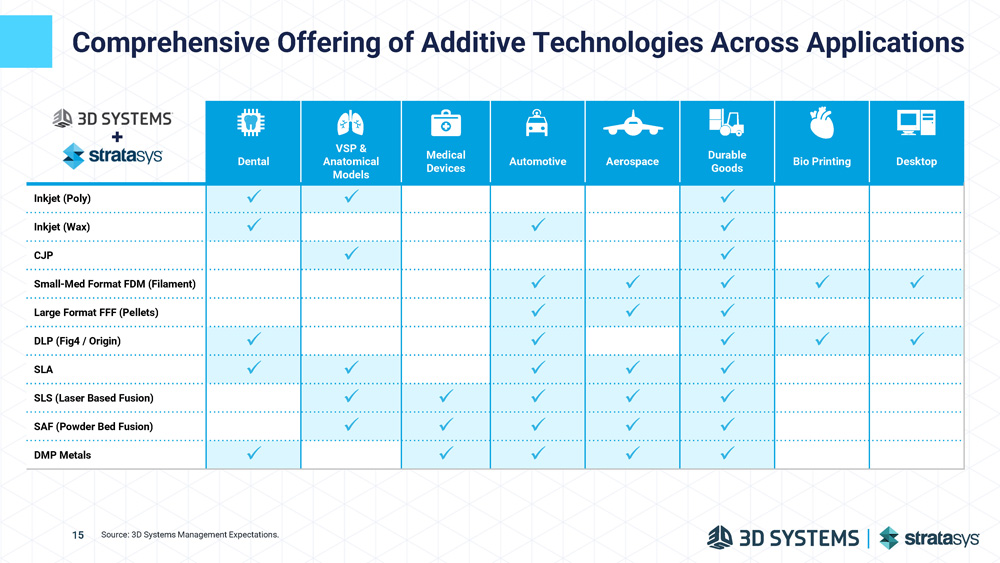

Comprehensive Offering of Additive Technologies Across Applications Desktop Bio Printing Durable Goods Aerospace Automotive Medical Devices VSP & Anatomical Models Dental x x x Inkjet (Poly) x x x Inkjet (Wax) x x CJP x x x x x Small - Med Format FDM (Filament) x x x Large Format FFF (Pellets) x x x x x DLP (Fig4 / Origin) x x x x x SLA x x x x x SLS (Laser Based Fusion) x x x x x SAF (Powder Bed Fusion) x x x x x DMP Metals 15 Source: 3D Systems Management Expectations.

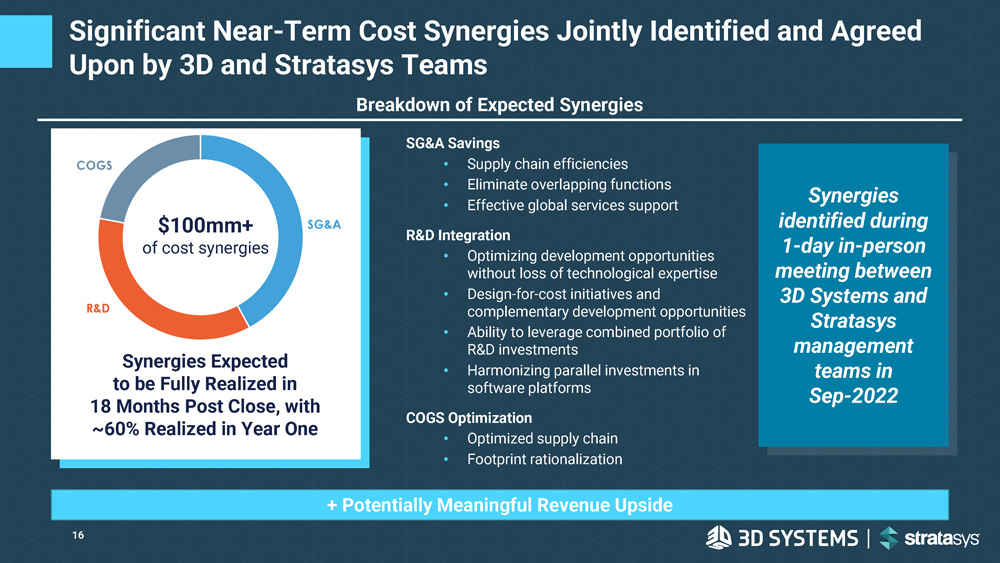

Significant Near - Term Cost Synergies Jointly Identified and Agreed Upon by 3D and Stratasys Teams SG&A Savings • Supply chain efficiencies • Eliminate overlapping functions • Effective global services support R&D Integration • Optimizing development opportunities without loss of technological expertise • Design - for - cost initiatives and complementary development opportunities • Ability to leverage combined portfolio of R&D investments • Harmonizing parallel investments in software platforms COGS Optimization • Optimized supply chain • Footprint rationalization SG&A R&D COGS $100mm+ of cost synergies Synergies Expected to be Fully Realized in 18 Months Post Close, with ~60% Realized in Year One 16 + Potentially Meaningful Revenue Upside Breakdown of Expected Synergies Synergies identified during 1 - day in - person meeting between 3D Systems and Stratasys management teams in Sep - 2022

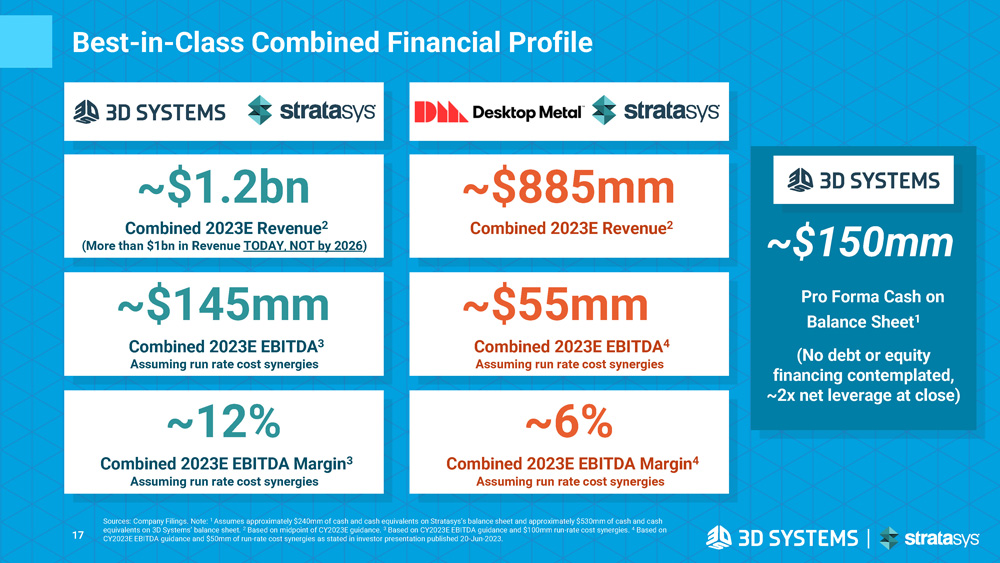

Best - in - Class Combined Financial Profile Sources: Company Filings. Note: 1 Assumes approximately $240mm of cash and cash equivalents on Stratasys’s balance sheet and approximately $530mm of cash and cash equivalents on 3D Systems’ balance sheet. 2 Based on midpoint of CY2023E guidance. 3 Based on CY2023E EBITDA guidance and $100mm run - rate cost synergies. 4 Based on CY2023E EBITDA guidance and $50mm of run - rate cost synergies as stated in investor presentation published 20 - Jun - 2023. 17 ~$1.2bn Combined 2023E Revenue 2 (More than $1bn in Revenue TODAY , NOT by 2026 ) ~$145mm Combined 2023E EBITDA 3 Assuming run rate cost synergies ~12% Combined 2023E EBITDA Margin 3 Assuming run rate cost synergies ~$885mm Combined 2023E Revenue 2 ~$55mm Combined 2023E EBITDA 4 Assuming run rate cost synergies ~6% Combined 2023E EBITDA Margin 4 Assuming run rate cost synergies ~$150mm Pro Forma Cash on Balance Sheet 1 (No debt or equity financing contemplated, ~2x net leverage at close)

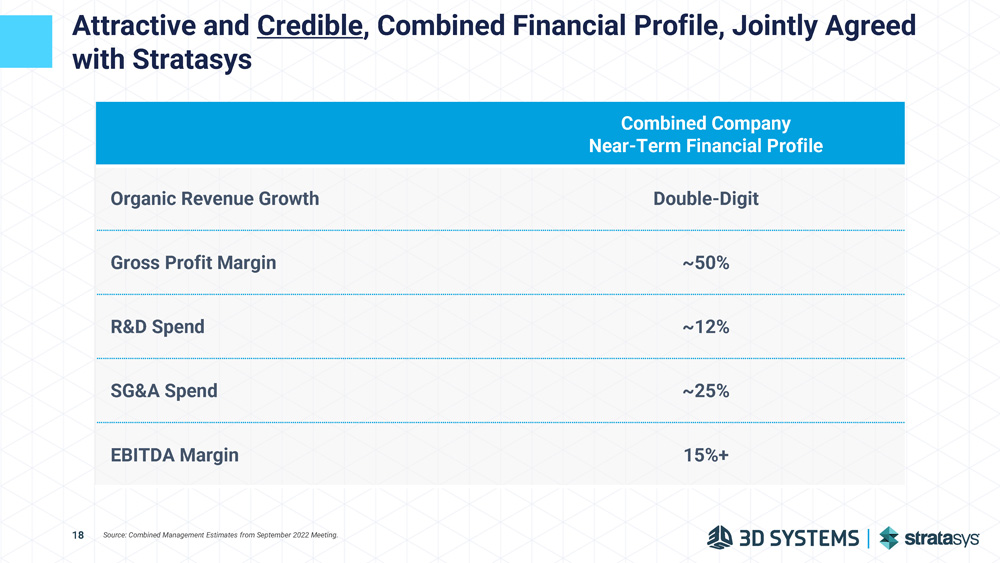

Attractive and Credible , Combined Financial Profile, Jointly Agreed with Stratasys 18 Source: Combined Management Estimates from September 2022 Meeting. Combined Company Near - Term Financial Profile Double - Digit Organic Revenue Growth ~50% Gross Profit Margin ~12% R&D Spend ~25% SG&A Spend 15%+ EBITDA Margin

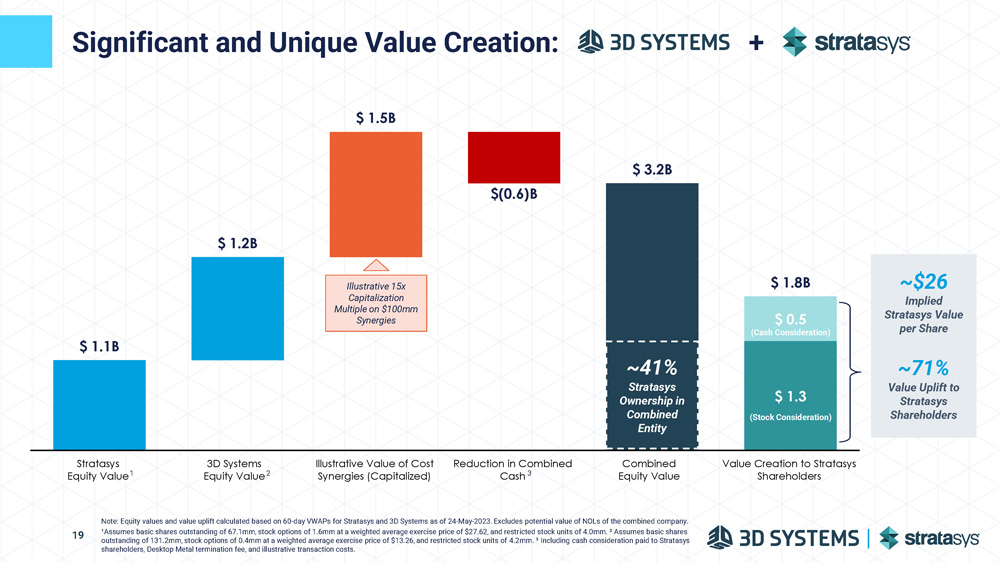

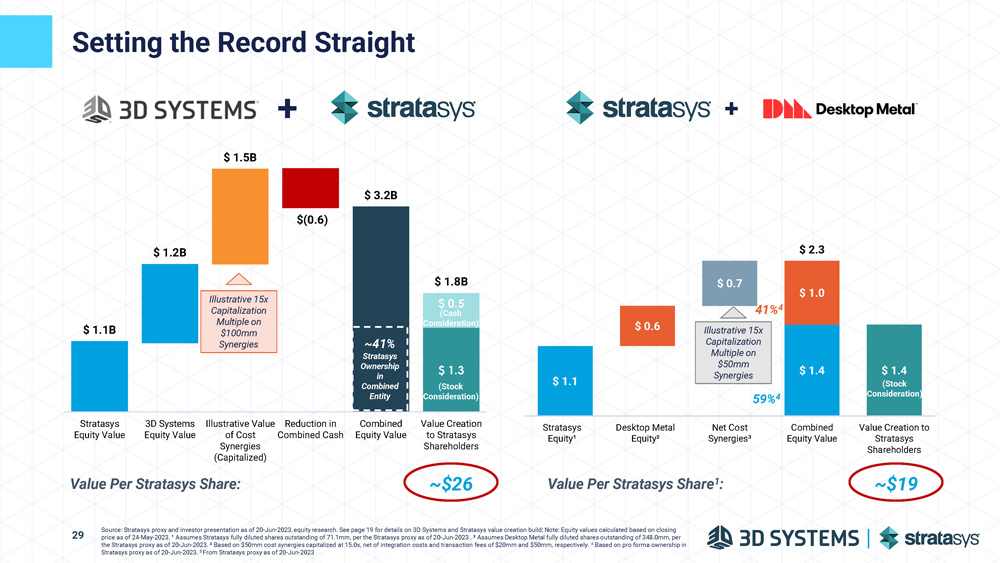

$ 1.1B $ 1.2B $ 1.5B $(0.6)B $ 3.2B $ 1.8B .50 $ 2.0 Illustrative Value of Cost Synergies (Capitalized) Combined Equity Value Value Creation to Stratasys Shareholders Significant and Unique Value Creation: + ~71% Value Uplift to Stratasys Shareholders ~$26 Implied Stratasys Value per Share Illustrative 15x Capitalization Multiple on $100mm Synergies ~41% Stratasys Ownership in Combined Entity $ 0.5 (Cash Consideration) $ 1.3 (Stock Consideration) Reduction in Combined Cash 3 Stratasys Equity Value 1 3D Systems Equity Value 2 Note: Equity values and value uplift calculated based on 60 - day VWAPs for Stratasys and 3D Systems as of 24 - May - 2023. Excludes potential value of NOLs of the combined company. ¹Assumes basic shares outstanding of 67.1mm, stock options of 1.6mm at a weighted average exercise price of $27.62, and restricted stock units of 4.0mm. ² Assumes basic shares outstanding of 131.2mm, stock options of 0.4mm at a weighted average exercise price of $13.26, and restricted stock units of 4.2mm. ³ Including cash consideration paid to Stratasys shareholders, Desktop Metal termination fee, and illustrative transaction costs. 19

Clearly Superior Proposal 20

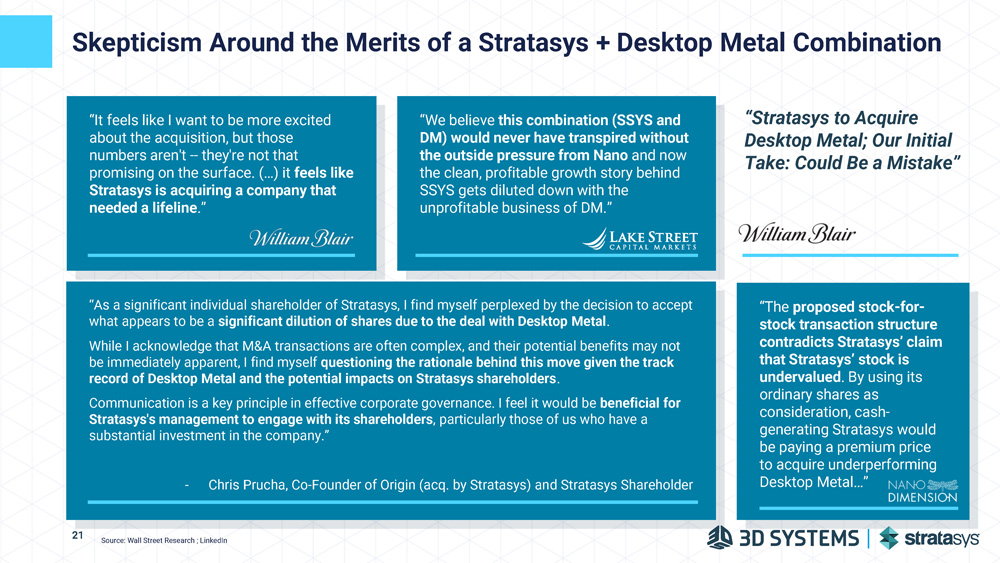

“We believe this combination (SSYS and DM) would never have transpired without the outside pressure from Nano and now the clean, profitable growth story behind SSYS gets diluted down with the unprofitable business of DM.” “The proposed stock - for - stock transaction structure contradicts Stratasys’ claim that Stratasys’ stock is undervalued . By using its ordinary shares as consideration, cash - generating Stratasys would be paying a premium price to acquire underperforming Desktop Metal…” “It feels like I want to be more excited about the acquisition, but those numbers aren't - - they're not that promising on the surface. (…) it feels like Stratasys is acquiring a company that needed a lifeline .” “As a significant individual shareholder of Stratasys, I find myself perplexed by the decision to accept what appears to be a significant dilution of shares due to the deal with Desktop Metal . While I acknowledge that M&A transactions are often complex, and their potential benefits may not be immediately apparent, I find myself questioning the rationale behind this move given the track record of Desktop Metal and the potential impacts on Stratasys shareholders . Communication is a key principle in effective corporate governance. I feel it would be beneficial for Stratasys's management to engage with its shareholders , particularly those of us who have a substantial investment in the company.” - Chris Prucha, Co - Founder of Origin (acq. by Stratasys) and Stratasys Shareholder “Stratasys to Acquire Desktop Metal; Our Initial Take: Could Be a Mistake” Skepticism Around the Merits of a Stratasys + Desktop Metal Combination 21 Source: Wall Street Research ; LinkedIn

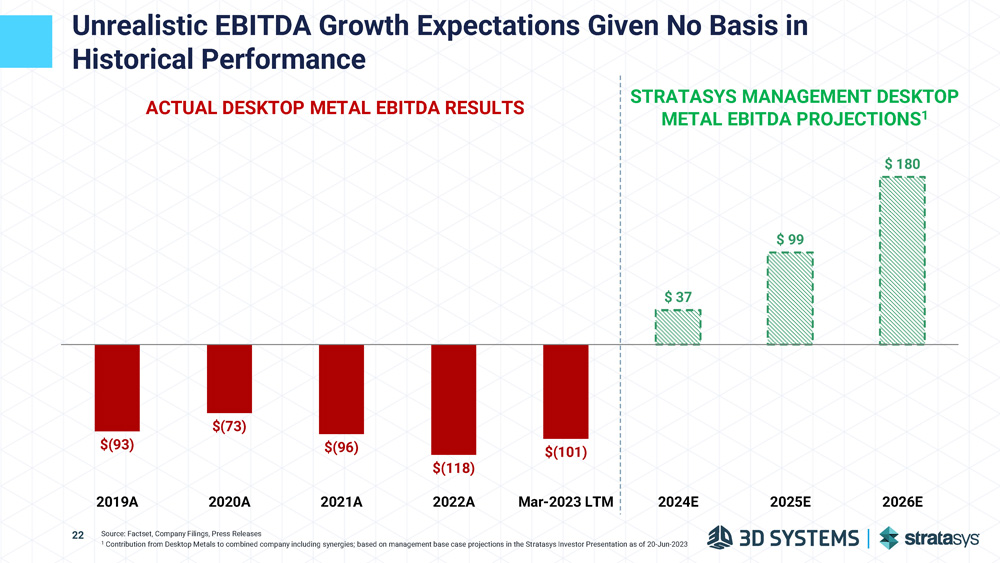

$(93) $(73) $(96) $(118) $(101) $ 99 $ 37 $ 180 0) $ 200 2025E 2026E Unrealistic EBITDA Growth Expectations Given No Basis in Historical Performance ACTUAL DESKTOP METAL EBITDA RESULTS 2019A 2020A 2021A 2022A Mar - 2023 LTM 2024E Source: Factset, Company Filings, Press Releases 1 Contribution from Desktop Metals to combined company including synergies; based on management base case projections in the Stratasys Investor Presentation as of 20 - Jun - 2023 STRATASYS MANAGEMENT DESKTOP METAL EBITDA PROJECTIONS 1 22

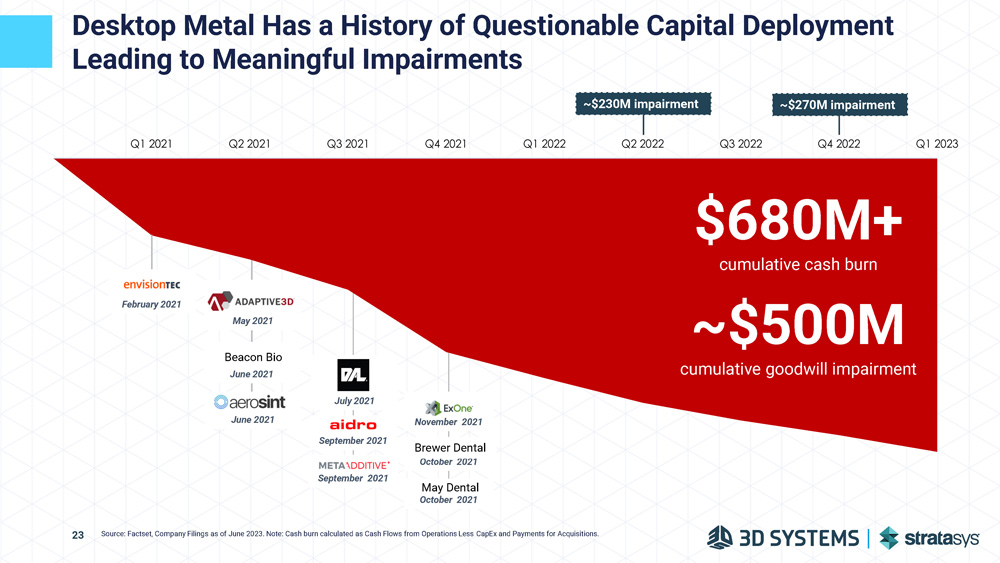

February 2021 September 2021 May 2021 June 2021 July 2021 September 2021 November 2021 May Dental October 2021 23 Desktop Metal Has a History of Questionable Capital Deployment Leading to Meaningful Impairments ~$270M impairment ~$230M impairment Q1 2023 Q4 2022 Q3 2022 Q2 2022 Q1 2022 Q4 2021 Q3 2021 Q2 2021 Q1 2021 $680M+ cumulative cash burn ~$500M cumulative goodwill impairment Source: Factset, Company Filings as of June 2023. Note: Cash burn calculated as Cash Flows from Operations Less CapEx and Payments for Acquisitions. Beacon Bio June 2021 Brewer Dental October 2021

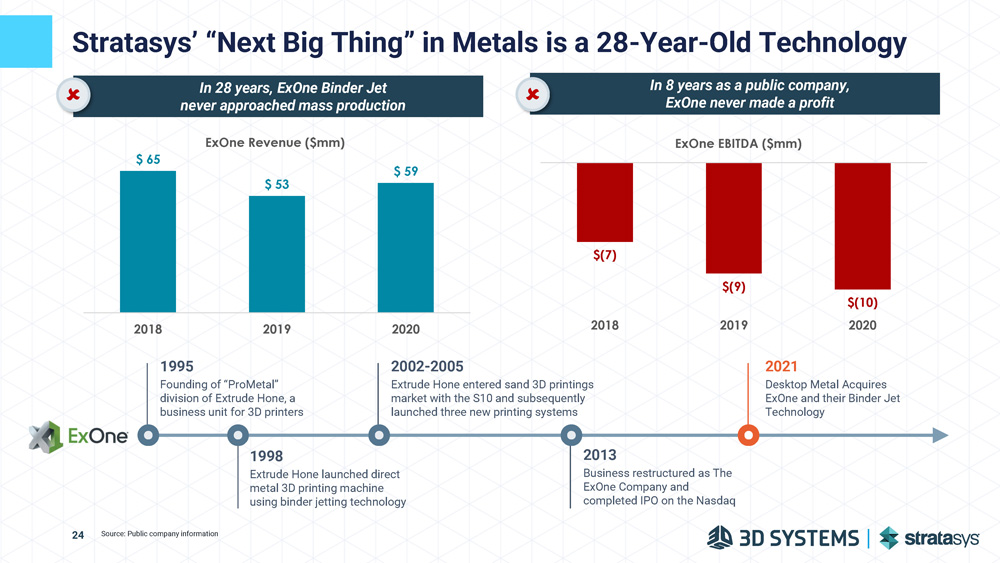

1998 Extrude Hone launched direct metal 3D printing machine using binder jetting technology Stratasys’ “Next Big Thing” in Metals is a 28 - Year - Old Technology 2021 Desktop Metal Acquires ExOne and their Binder Jet Technology 2002 - 2005 Extrude Hone entered sand 3D printings market with the S10 and subsequently launched three new printing systems 2013 Business restructured as The ExOne Company and completed IPO on the Nasdaq Source: Public company information In 8 years as a public company, ExOne never made a profit $ 65 $ 53 $ 59 2018 2019 1995 Founding of “ProMetal” division of Extrude Hone, a business unit for 3D printers 2020 ExOne Revenue ($mm) $(7) $(9) 2018 2019 $(10) 2020 ExOne EBITDA ($mm) In 28 years, ExOne Binder Jet never approached mass production 24

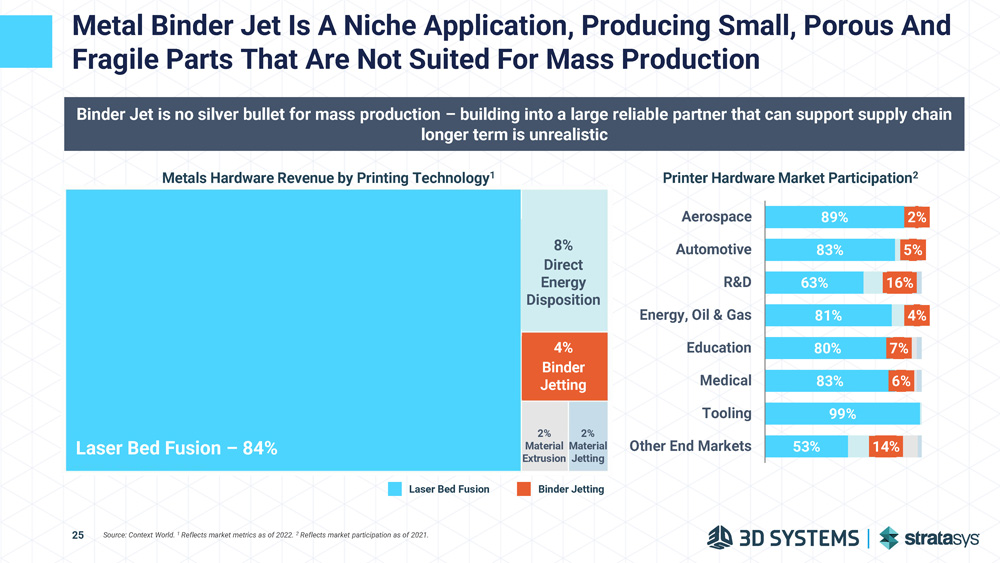

83% 63% 81% 80% 83% 99% 53% 5% 16% 4% 7% 6% 14% Aerospace 89% 2% Automotive R&D Energy, Oil & Gas Education Medical Tooling Other End Markets Metal Binder Jet Is A Niche Application, Producing Small, Porous And Fragile Parts That Are Not Suited For Mass Production 25 Source: Context World. 1 Reflects market metrics as of 2022. 2 Reflects market participation as of 2021. Binder Jet is no silver bullet for mass production – building into a large reliable partner that can support supply chain longer term is unrealistic Metals Hardware Revenue by Printing Technology 1 Printer Hardware Market Participation 2 Laser Bed Fusion Binder Jetting Laser Bed Fusion – 84% 8% Direct Energy Disposition 4% Binder Jetting 2% Material Extrusion l 2% Materi a Jetting

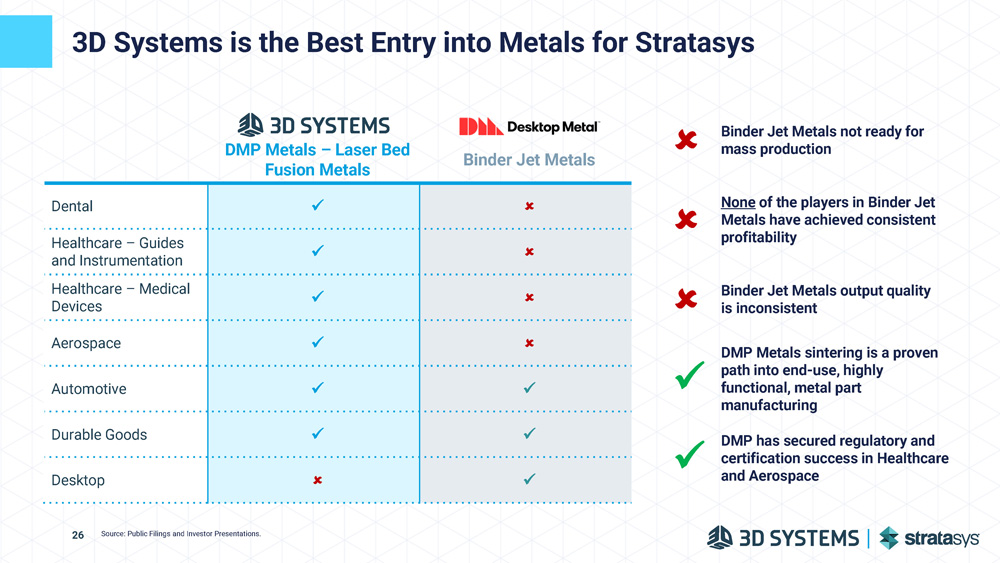

3D Systems is the Best Entry into Metals for Stratasys Binder Jet Metals DMP Metals – Laser Bed Fusion Metals x Dental x Healthcare – Guides and Instrumentation x Healthcare – Medical Devices x Aerospace x x Automotive x x Durable Goods x Desktop Binder Jet Metals not ready for mass production None of the players in Binder Jet Metals have achieved consistent profitability Binder Jet Metals output quality is inconsistent Source: Public Filings and Investor Presentations. 26 DMP Metals sintering is a proven path into end - use, highly functional, metal part manufacturing DMP has secured regulatory and certification success in Healthcare and Aerospace x x

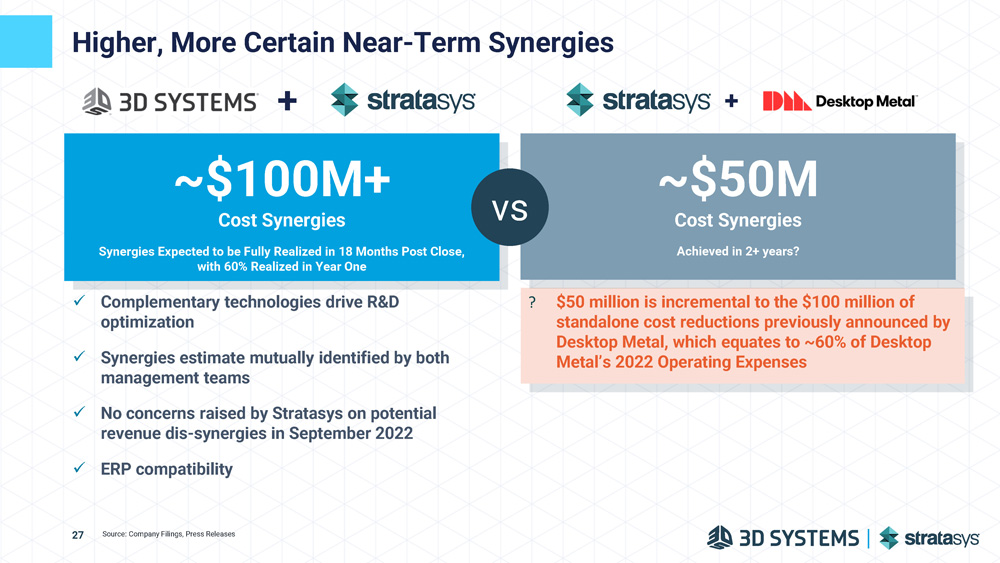

Higher, More Certain Near - Term Synergies + ~$50M Cost Synergies Achieved in 2+ years? ~$100M+ ? $50 million is incremental to the $100 million of standalone cost reductions previously announced by Desktop Metal, which equates to ~60% of Desktop Metal’s 2022 Operating Expenses Cost Synergies Synergies Expected to be Fully Realized in 18 Months Post Close, with 60% Realized in Year One x Complementary technologies drive R&D optimization x Synergies estimate mutually identified by both management teams x No concerns raised by Stratasys on potential revenue dis - synergies in September 2022 x ERP compatibility vs Source: Company Filings, Press Releases 27

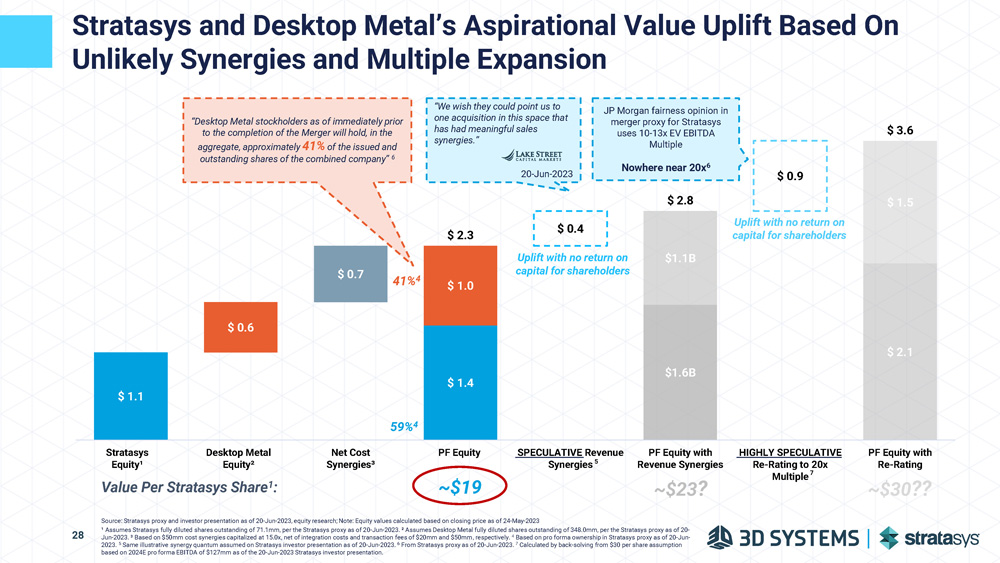

$ 1.1 $ 0.6 $ 0.7 $ 1.4 $ 1.0 $ 0.4 $1.6B $1.1B $ 0.9 $ 2.1 $ 1.5 $ 2.3 $ 2.8 $ 3.6 Stratasys Equity¹ Desktop Metal Equity² Net Cost Synergies³ PF Equity Stratasys and Desktop Metal’s Aspirational Value Uplift Based On Unlikely Synergies and Multiple Expansion Source: Stratasys proxy and investor presentation as of 20 - Jun - 2023, equity research; Note: Equity values calculated based on closing price as of 24 - May - 2023 28 ¹ Assumes Stratasys fully diluted shares outstanding of 71.1mm, per the Stratasys proxy as of 20 - Jun - 2023. ² Assumes Desktop Metal fully diluted shares outstanding of 348.0mm, per the Stratasys proxy as of 20 - Jun - 2023. ³ Based on $50mm cost synergies capitalized at 15.0x, net of integration costs and transaction fees of $20mm and $50mm, respectively. 4 Based on pro forma ownership in Stratasys proxy as of 20 - Jun - 2023. 5 Same illustrative synergy quantum assumed on Stratasys investor presentation as of 20 - Jun - 2023. 6 From Stratasys proxy as of 20 - Jun - 2023. 7 Calculated by back - solving from $30 per share assumption based on 2024E pro forma EBITDA of $127mm as of the 20 - Jun - 2023 Stratasys investor presentation. 59% 4 41% 4 JP Morgan fairness opinion in merger proxy for Stratasys uses 10 - 13x EV EBITDA Multiple Nowhere near 20x 6 “We wish they could point us to one acquisition in this space that has had meaningful sales synergies.” 20 - Jun - 2023 Value Per Stratasys Share 1 : ~$19 PF Equity with Revenue Synergies ~$23 ? PF Equity with Re - Rating ~$30 ?? SPECULATIVE Revenue Synergies 5 HIGHLY SPECULATIVE Re - Rating to 20x Multiple 7 Uplift with no return on capital for shareholders Uplift with no return on capital for shareholders “Desktop Metal stockholders as of immediately prior to the completion of the Merger will hold, in the aggregate, approximately 41% of the issued and outstanding shares of the combined company” 6

$ 1.1 $ 0.6 $ 0.7 $ 1.4 $ 1.0 $ 2.3 Stratasys Equity¹ Desktop Metal Equity² Net Cost Synergies³ Combined Equity Value Value Creation to Stratasys Shareholders Setting the Record Straight 29 Source: Stratasys proxy and investor presentation as of 20 - Jun - 2023, equity research. See page 19 for details on 3D Systems and Stratasys value creation build; Note: Equity values calculated based on closing price as of 24 - May - 2023. ¹ Assumes Stratasys fully diluted shares outstanding of 71.1mm, per the Stratasys proxy as of 20 - Jun - 2023 . ² Assumes Desktop Metal fully diluted shares outstanding of 348.0mm, per the Stratasys proxy as of 20 - Jun - 2023. ³ Based on $50mm cost synergies capitalized at 15.0x, net of integration costs and transaction fees of $20mm and $50mm, respectively. 4 Based on pro forma ownership in Stratasys proxy as of 20 - Jun - 2023. 5 From Stratasys proxy as of 20 - Jun - 2023 Value Per Stratasys Share 1 : 59% 4 41% 4 ~$19 + $ 1.1B $ 1.2B $ 1.5B $(0.6) $ 3.2B $ 1.8B Stratasys Equity Value 3D Systems Equity Value Synergies (Capitalized) Illustrative Value Reduction in of Cost Combined Cash Combined Equity Value Value Creation to Stratasys Shareholders Value Per Stratasys Share: ~$26 ~41% Stratasys Ownership in Combined Entity Illustrative 15 x Capitalization Multiple on $100mm Synergies $ 0.5 (Cash Consideration) $ 1.3 (Stock Consideration) Illustrative 15 x Capitalization Multiple on $50mm Synergies $ 1.4 (Stock Consideration)

Conclusion 30

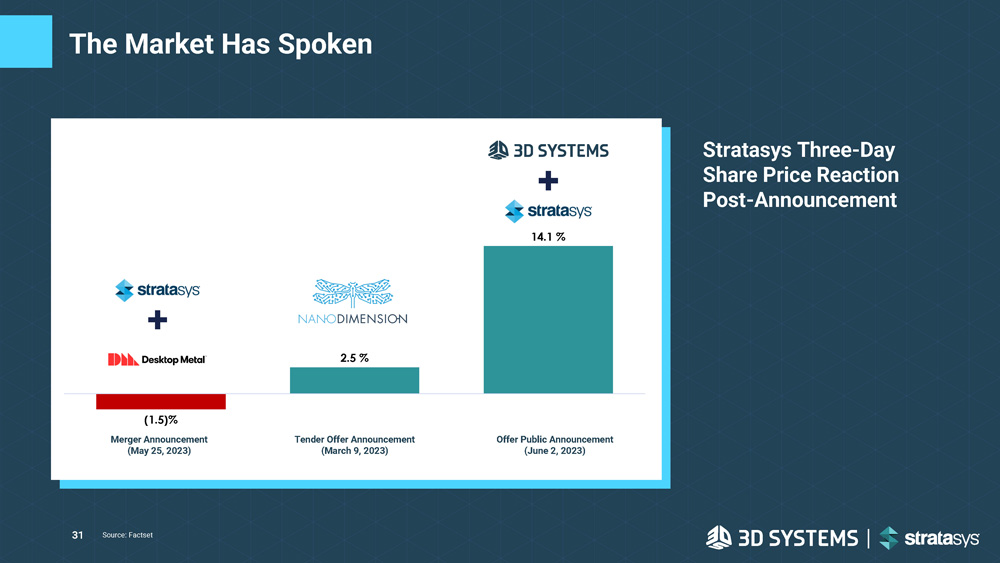

2.5 % 14.1 % SSYS + DM Merger Announcement (25 - May - 23) Nano Tender Offer Announcement (09 - Mar - 23) 3D Systems Offer Announcement (02 - Jun - 23) The Market Has Spoken Source: Factset Stratasys Three - Day Share Price Reaction Post - Announcement 31 (1.5)% Merger Announcement (May 25, 2023) Tender Offer Announcement (March 9, 2023) Offer Public Announcement (June 2, 2023)

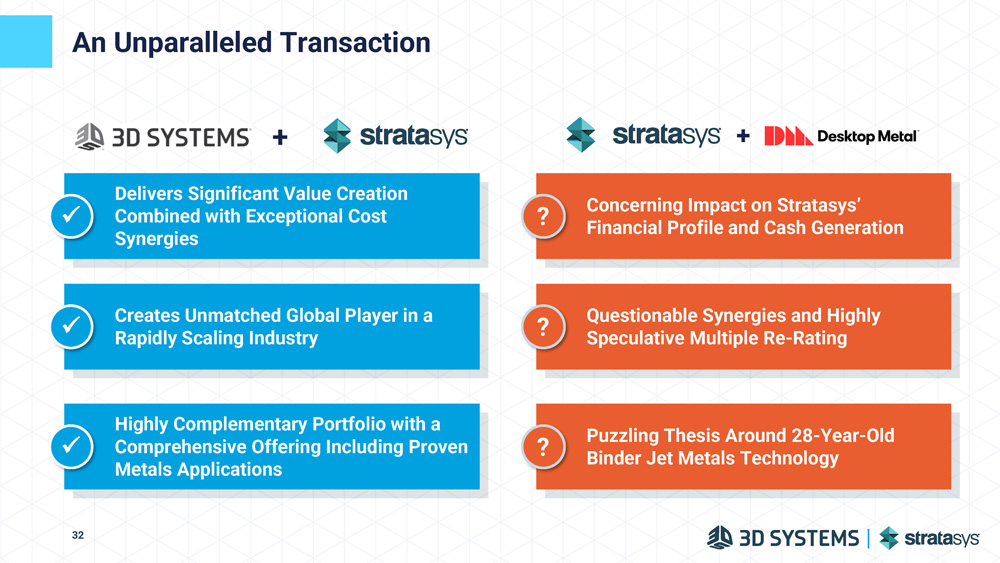

An Unparalleled Transaction 32 + Creates Unmatched Global Player in a Rapidly Scaling Industry x Highly Complementary Portfolio with a Comprehensive Offering Including Proven Metals Applications x Delivers Significant Value Creation Combined with Exceptional Cost Synergies x ? Puzzling Thesis Around 28 - Year - Old Binder Jet Metals Technology Questionable Synergies and Highly Speculative Multiple Re - Rating ? Concerning Impact on Stratasys’ Financial Profile and Cash Generation ?

Appendix 33

Experienced 3D Systems Management Team Jeff Graves CEO • Joined in May 2020 • Experience: Previous President & CEO of MTS Systems; Former President & CEO of C&D Technologies; Former Operating Officer & CEO of Kemet Corporations Michael Turner CFO • Joined in August 2022 • Experience: Former CFO of Innovative Chemical Products; Previous Business Unit CFO at Albemarle; Held Leadership positions at Albemarle, FMC, and Polypore International Menno Ellis EVP, Healthcare Solutions • Joined in December 2016 • Experience: Founder and Former President of The Kaminda Group; Former Partner at ABA Consulting Charles Hull Co - Founder, CTO for Regenerative Medicine • Founded 3D Systems in 1986 • Inventions: Stereolithography, the first commercial 3D printing technology, and 85 US patents • Recognition: National Inventors Hall of Fame Inductee; recipient of European Patent Office’s prestigious European Inventor Award Andrew Johnson Chief Corporate Development Officer, and Chief Legal Counsel • Joined in July 2006 • Experience: Served as Interim President and CEO of 3D Systems from Oct - 2015 to Apr - 2016; Associate with Hunton & Williams LLP; Co - Founder, Director of Hail! Impact Phyllis Nordstrom Chief People Officer, and Chief Administrative Officer • Joined in September 2021 • Experience: Former SVP & Chief Risk & Compliance Officer at MTS; Previous Risk Assurance Director at PWC Reji Puthenveetil EVP, Industrial Solutions • Joined in October 2020 • Experience: Former Managing Partner of ABA Consulting; Former Engagement Manager at M/A/R/C Consulting; Founder of Group Newhouse Dr. Joe Zuiker EVP, Engineering and Operation • Joined in December 2022 • Experience: Former VP of Engineering and Operations at MTS, Senior Director of Technology at Halliburton, and General Manager at GE Vernova 34

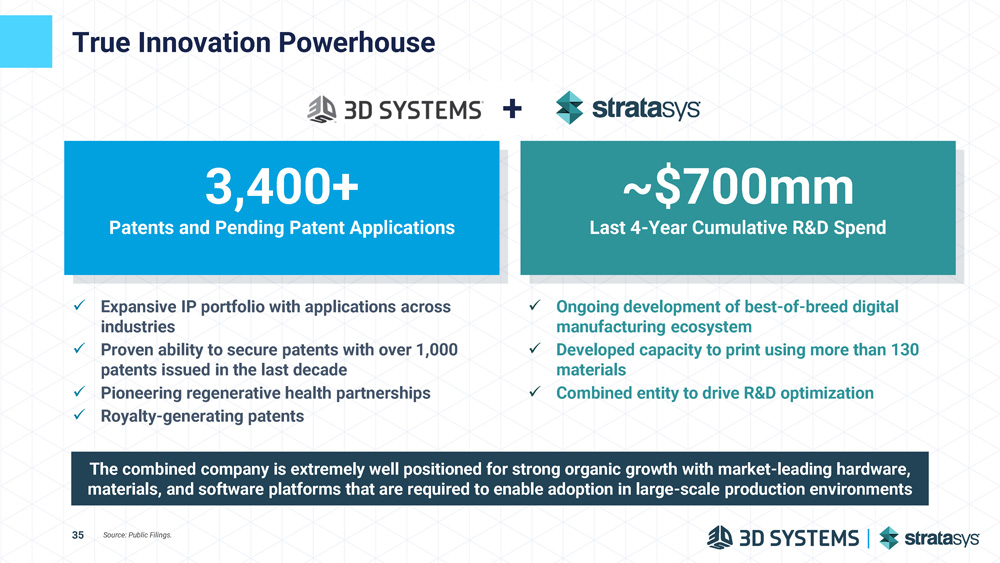

True Innovation Powerhouse + ~$700mm Last 4 - Year Cumulative R&D Spend 3,400+ Patents and Pending Patent Applications x Ongoing development of best - of - breed digital manufacturing ecosystem x Developed capacity to print using more than 130 materials x Combined entity to drive R&D optimization x Expansive IP portfolio with applications across industries x Proven ability to secure patents with over 1,000 patents issued in the last decade x Pioneering regenerative health partnerships x Royalty - generating patents 35 The combined company is extremely well positioned for strong organic growth with market - leading hardware, materials, and software platforms that are required to enable adoption in large - scale production environments Source: Public Filings.

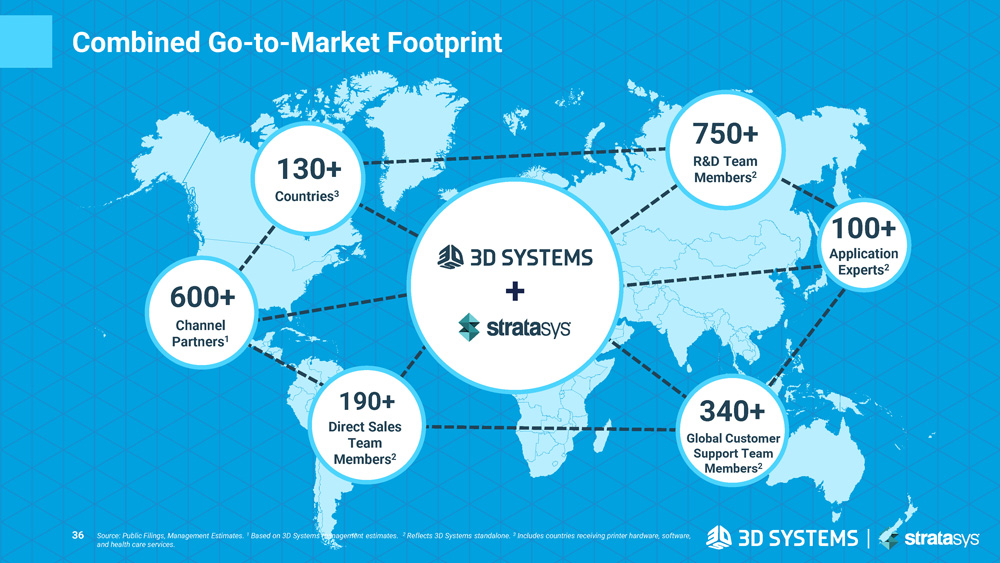

Combined Go - to - Market Footprint 130+ Countries 3 600+ Channel Partners 1 190+ Direct Sales Team Members 2 340+ Global Customer Support Team Members 2 750+ R&D Team Members 2 100+ Application Experts 2 + 36 Source: Public Filings, Management Estimates. 1 Based on 3D Systems management estimates. 2 Reflects 3D Systems standalone. 3 Includes countries receiving printer hardware, software, and health care services.

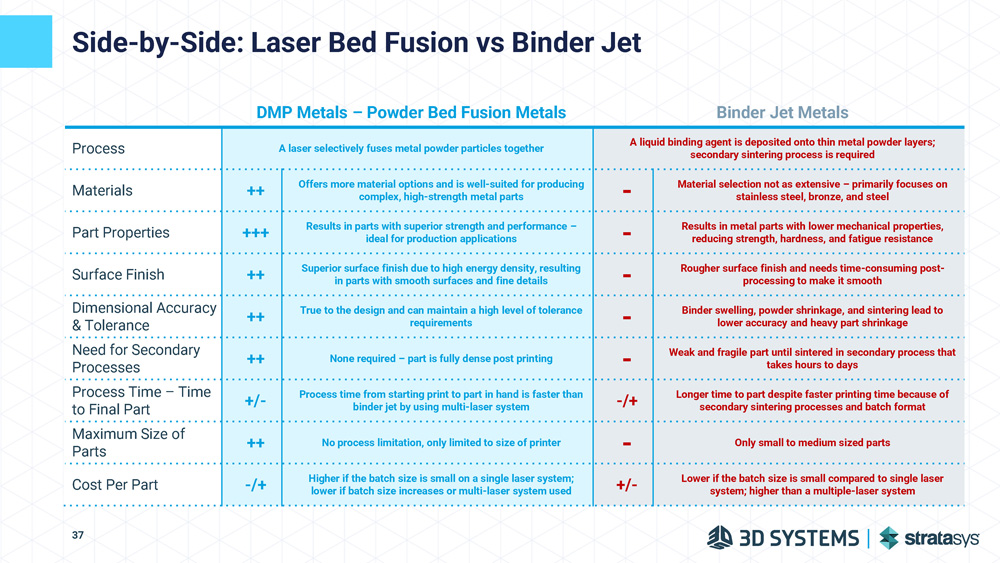

Side - by - Side: Laser Bed Fusion vs Binder Jet 37 Binder Jet Metals DMP Metals – Powder Bed Fusion Metals A liquid binding agent is deposited onto thin metal powder layers; secondary sintering process is required A laser selectively fuses metal powder particles together Process Material selection not as extensive – primarily focuses on stainless steel, bronze, and steel - Offers more material options and is well - suited for producing complex, high - strength metal parts ++ Materials Results in metal parts with lower mechanical properties, reducing strength, hardness, and fatigue resistance - Results in parts with superior strength and performance – ideal for production applications +++ Part Properties Rougher surface finish and needs time - consuming post - processing to make it smooth - Superior surface finish due to high energy density, resulting in parts with smooth surfaces and fine details ++ Surface Finish Binder swelling, powder shrinkage, and sintering lead to lower accuracy and heavy part shrinkage - True to the design and can maintain a high level of tolerance requirements ++ Dimensional Accuracy & Tolerance Weak and fragile part until sintered in secondary process that takes hours to days - None required – part is fully dense post printing ++ Need for Secondary Processes Longer time to part despite faster printing time because of secondary sintering processes and batch format - /+ Process time from starting print to part in hand is faster than binder jet by using multi - laser system +/ - Process Time – Time to Final Part Only small to medium sized parts - No process limitation, only limited to size of printer ++ Maximum Size of Parts Lower if the batch size is small compared to single laser system; higher than a multiple - laser system +/ - Higher if the batch size is small on a single laser system; lower if batch size increases or multi - laser system used - /+ Cost Per Part

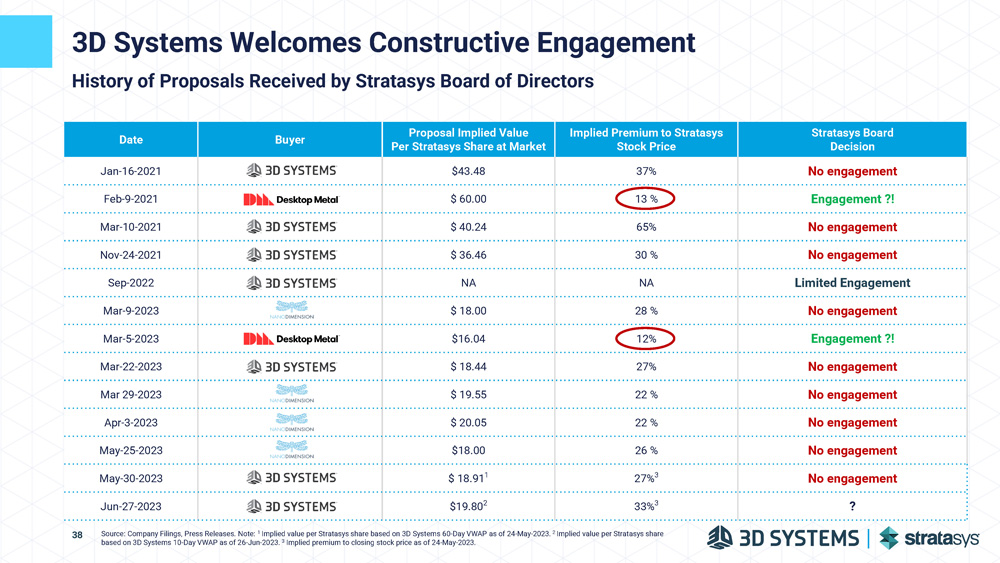

3D Systems Welcomes Constructive Engagement Stratasys Board Decision Implied Premium to Stratasys Stock Price Proposal Implied Value Per Stratasys Share at Market Buyer Date No engagement 37% $43.48 Jan - 16 - 2021 Engagement ?! 13 % $ 60.00 Feb - 9 - 2021 No engagement 65% $ 40.24 Mar - 10 - 2021 No engagement 30 % $ 36.46 Nov - 24 - 2021 Limited Engagement NA NA Sep - 2022 No engagement 28 % $ 18.00 Mar - 9 - 2023 Engagement ?! 12% $16.04 Mar - 5 - 2023 No engagement 27% $ 18.44 Mar - 22 - 2023 No engagement 22 % $ 19.55 Mar 29 - 2023 No engagement 22 % $ 20.05 Apr - 3 - 2023 No engagement 26 % $18.00 May - 25 - 2023 No engagement 27% 3 $ 18.91 1 May - 30 - 2023 ? 33% 3 $19.80 2 Jun - 27 - 2023 History of Proposals Received by Stratasys Board of Directors Source: Company Filings, Press Releases. Note: 1 Implied value per Stratasys share based on 3D Systems 60 - Day VWAP as of 24 - May - 2023. 2 Implied value per Stratasys share based on 3D Systems 10 - Day VWAP as of 26 - Jun - 2023. 3 Implied premium to closing stock price as of 24 - May - 2023. 38

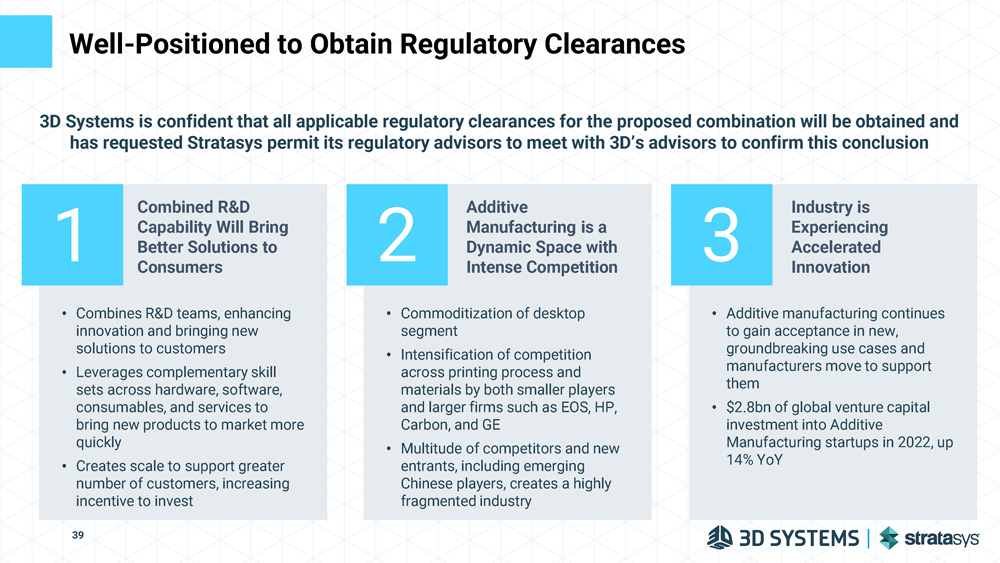

Well - Positioned to Obtain Regulatory Clearances • Commoditization of desktop segment • Intensification of competition across printing process and materials by both smaller players and larger firms such as EOS, HP, Carbon, and GE • Multitude of competitors and new entrants, including emerging Chinese players, creates a highly fragmented industry 2 • Additive manufacturing continues to gain acceptance in new, groundbreaking use cases and manufacturers move to support them • $2.8bn of global venture capital investment into Additive Manufacturing startups in 2022, up 14% YoY 3 • Combines R&D teams, enhancing innovation and bringing new solutions to customers • Leverages complementary skill sets across hardware, software, consumables, and services to bring new products to market more quickly • Creates scale to support greater number of customers, increasing incentive to invest 1 3D Systems is confident that all applicable regulatory clearances for the proposed combination will be obtained and has requested Stratasys permit its regulatory advisors to meet with 3D’s advisors to confirm this conclusion Combined R&D Capability Will Bring Better Solutions to Consumers Additive Manufacturing is a Dynamic Space with Intense Competition Industry is Experiencing Accelerated Innovation 39